-

INTRODUCTION TO HYDROGEN ENERGYBOHUI TE PROVIDES CUSTOMERS WITH INTELLIGENT PRODUCTION LINE SOLUTIONS FOR ELECTROLYTIC CELLS, INCLUDING INTELLIGENT PRODUCTION LINE PROCESSES FOR ELEDetail

-

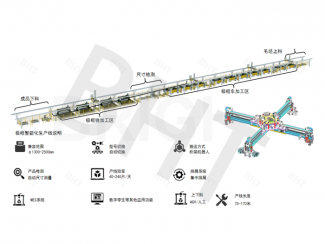

ELECTROLYZER SMART FACTORY (2.5GWH ELECTROLYZER INTELLIGENT MANUFACTURING SOLUTION)Suitable for 200-2000Nm³/h alkaline water electrolyzer; 4-200Nm³/h PEM electrolyzer

Low cost and high efficiency: Provide one-stop service, reduce costs in the whole process, and achieve efficient production.

Safe and stable: Set up safety valves, interlock alarms, and automatic interlock shutdown for misoperation to reduce human error rate and safety risks

Convenient installation: The prefabricated operating platform is used to facilitate installation and later disassembly and maintenance.

Ergonomic design: design the operation and maintenance structure according to the ergonomic method, and fully consider the platform and passage required for daily operation and maintenance

Intelligent control: automatic control of equipment, valves and meters, intelligent multi-level control (five-layer safety protection design), DCS monitoring in the central control room, and SIS/GDS monitoring system for PLC control management.Detail

-

About usGroup profile Qualification Corporate culture Competitiveness Global layout

-

Product3C semiconductor Hydrogen Energy Automotive Related Equipment

-

ServiceResource Q&A

-

NewsCompany news Exhibition

Contact us

Copyright @ 2022-2023 Bright Automatrix Inc.