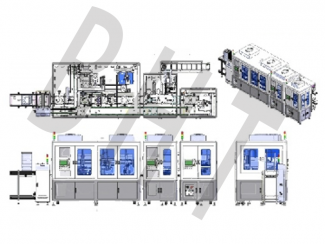

Chip inverted film crystal expandingline

Our company has independently developed a complete line equipment for chip blue film inversion and crystal expansion, with complete supporting facilities and simplified process flow

Clear, pioneering in the industry. Integrated and simplified the process flow, improving production efficiency; Reduced intermediate links and improved quality

Rate. Integrated static elimination throughout the entire production process, further reducing quality risks. At the same time, the entire production line design has data traceability function to ensure accurate tracking and binding of the product production process.

Clear, pioneering in the industry. Integrated and simplified the process flow, improving production efficiency; Reduced intermediate links and improved quality

Rate. Integrated static elimination throughout the entire production process, further reducing quality risks. At the same time, the entire production line design has data traceability function to ensure accurate tracking and binding of the product production process.

Product application areas

Our company has independently developed a complete line equipment for chip blue film inversion and crystal expansion, with complete supporting facilities and simplified process flow

Clear, pioneering in the industry. Integrated and simplified the process flow, improving production efficiency; Reduced intermediate links and improved quality

Rate. Integrated static elimination throughout the entire production process, further reducing quality risks. At the same time, the entire production line design has data traceability function to ensure accurate tracking and binding of the product production process.

Key parameters:

Line size: L7000xW1700xH1900mm (excluding FFU and tri color lights)

Applicable product specifications: Surface mount ring L220xW220xT1.0mm; Expansion ring 6 hours (customizable)

UPH:150PCS/H (Depending on the specific process)

Chip retention rate: ≤ 0.2%

Clear, pioneering in the industry. Integrated and simplified the process flow, improving production efficiency; Reduced intermediate links and improved quality

Rate. Integrated static elimination throughout the entire production process, further reducing quality risks. At the same time, the entire production line design has data traceability function to ensure accurate tracking and binding of the product production process.

Key parameters:

Line size: L7000xW1700xH1900mm (excluding FFU and tri color lights)

Applicable product specifications: Surface mount ring L220xW220xT1.0mm; Expansion ring 6 hours (customizable)

UPH:150PCS/H (Depending on the specific process)

Chip retention rate: ≤ 0.2%

Related product

-

Chip inverted film crystal expandinglineDetail