-

Highlights advantageSolid testing, assembly, packaging equipment development and integration capabilities, with core competitive advantages in automation control systems, sound and optical testing technology, and system integration;

Fully capable of providing the best one-stop professional services, standardized, modular, and universal design, offering the best cost-effectiveness and efficient automation systems;

Having the ability to deliver the entire production line/factory and rich experience in implementing case studies.Detail -

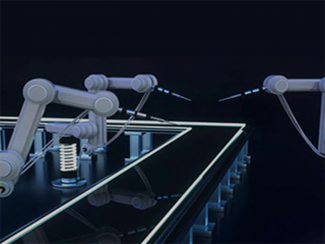

MMI ONLINE TESTINGThe MMI online testing system is a highly integrated and fully automated online testing line, consisting of 8

The test consists of two docking stations and two robotic arms.

The device can achieve automatic loading and unloading, automatic transmission of workstation testing, and synchronously complete 32 mobile phones

Detection of test items. At present, the production capacity can reach 350pcs/h.Detail -

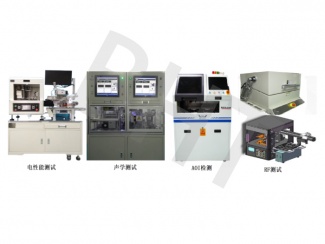

PRECISION TESTING EQUIPMENTProvide high-precision functional testing of electrical performance, acoustics, optics, RF and other products.Detail

-

AUTOMATIC ASSEMBLY LINE FOR HEADPHONE CHARGERSThe automatic assembly line consists of 14 workstations, with an overall length of ≤ 18m and a width of ≤ 1.2m. It includes lifting and reflux, Button feeding, protective film application, flipping, hot melt adhesive application, magnet installation, pressure holding 1, AB adhesive application, Shield iron sheet application, pressure holding 2, foam application, pressure holding 3, lifting and lowering reflux, and material receiving swing.Detail

-

FULLY AUTOMATIC INTELLIGENT PACKAGING LINEThe line body is composed of finished product inspection, laser logo information, product packaging, film coating and corner cutting machine, constant temperature over plastic, and finally easy to peel adhesive equipment, achieving fully automatic and intelligent packaging of products.Detail

-

FULLY AUTOMATIC HEAT SHRINK FILM BOTTOM SEALING AND CORNER CUTTING MACHINEThis device is mainly used for bottom sealing and cutting packaging of heat shrink film in product packaging boxes, achieving one-step sealing and cutting shrinkage.Detail

-

FULLY AUTOMATIC HEAT SHRINK FILM SEALING AND CORNER CUTTING MACHINEThis equipment is mainly used for sealing and cutting the middle part of the heat shrink film in product packaging boxes, achieving one-step sealing and cutting shrinkage。Detail

-

CLAMPING FIXTUREProvide assembly and testing fixtures for various processes of consumer electronics products.Detail

-

About usGroup profile Qualification Corporate culture Competitiveness Global layout

-

Product3C semiconductor Hydrogen Energy Automotive Related Equipment

-

ServiceResource Q&A

-

NewsCompany news Exhibition

Contact us

Copyright @ 2022-2023 Bright Automatrix Inc.

Are you interested in being

Are you interested in beinga great listed company?

+86-135 1084 6501

+86-135 1084 6501

info_433227

info_433227

David.Cao@bright-ai.com

David.Cao@bright-ai.com