-

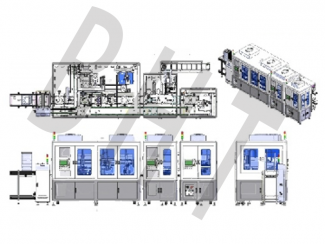

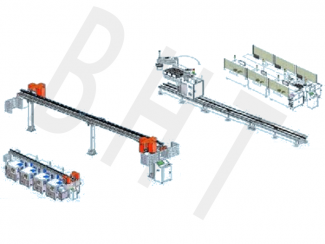

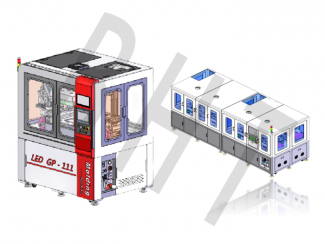

Chip inverted film crystal expandinglineOur company has independently developed a complete line equipment for chip blue film inversion and crystal expansion, with complete supporting facilities and simplified process flow

Clear, pioneering in the industry. Integrated and simplified the process flow, improving production efficiency; Reduced intermediate links and improved quality

Rate. Integrated static elimination throughout the entire production process, further reducing quality risks. At the same time, the entire production line design has data traceability function to ensure accurate tracking and binding of the product production process.Detail -

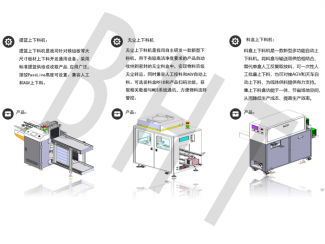

AUTOMATIC WAFER TEARING MACHINEFully automatic wafer tearing machine applied to BGA, QFN

FC、FO、Memory During the film tearing process, this equipment has the characteristics of uniform film tearing speed, stable film tearing, no fragments, and strong compatibility. Suitable for all thicknesses up to 100um~

600um BG film, UV film, etc. It can be paired with UV glue remover according to process requirements.Detail -

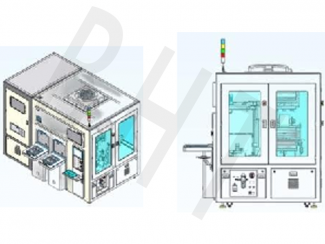

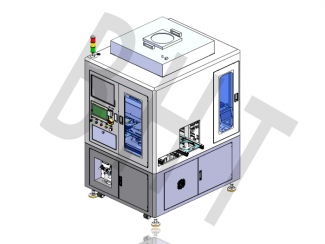

COMPRESSION MOLDING MACHINEThe fully automatic molding machine belongs to the semiconductor packaging equipment, which is used in the post packaging film pressing process of chips and can also be used in the chip plastic packaging process. Using release film assisted packaging, the packaging adhesive is flattened and cured on the surface of the substrate or module to form a protective film,

It provides waterproof, dustproof, and anti-collision protection for chips and other components. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.Detail -

AOI DETECTORAOI inspection machine is a visual inspection equipment developed by our company for chips in new cutting processes, used to control quality issues such as cutting size and appearance. We use independently developed visual systems and algorithm software to detect the cutting quality of chips from both sides. It can be operated as a standalone machine or produced online in a production line; Compatible with manual and crane loading and unloading.Detail

-

AUTOMATIC WAFER LAMINATING MACHINEThe wafer automatic film sticking machine is a specialized film sticking process developed by our company for BGA, QFN, FC, FO, Memory and other manufacturing processes. This equipment has the characteristics of uniform film sticking speed, no bubbles, no fragments, no wrinkles, etc. Suitable for all BG films with thicknesses ranging from 100um to 600um, V-notch cutting can be performed according to process requirements, and the height of the worktable and film pressure can be adjusted according to different products. After microscopic comparison and grinding verification, its film cutting accuracy, edge contour, sealing quality and other indicators are superior to similar imported equipmentDetail

-

WAFER VACUUM COATING MACHINEThe fully automatic wafer vacuum film sticking machine is applied to the automatic edge cutting and vacuum bonding of protective films for semiconductor silicon wafer etching and other processes. It is the first domestically developed and finalized equipment independently designed and manufactured by our company. After microscopic comparison verification, its film cutting accuracy, edge contour, sealing quality and other indicators are superior to similar imported equipment. By using a quick change stage, it is possible to quickly correspond to wafers of different sizes at 8 o’clock/12 o’clock.Detail

-

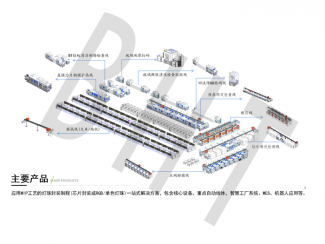

INTELLIGENT TRANSMISSION SYSTEMCrane transmission system

The overhead crane is a material conveying and handling equipment developed by our company for intelligent line bodies, used to load and unload various automated equipment inside the line body Material. Small footprint, high stability, labor-saving, and can achieve unmanned operation.

Ground rail transmission system

The ground rail transport vehicle is an unmanned plant guarding loading and unloading system developed by our company to solve customer labor pain points and integrate existing customer resources. It is used for centralized automatic loading and unloading of equipment such as welding wire machines and solidification machines, reducing labor demand. Can be connected to AGV, laying the foundation for future black light factories.Detail -

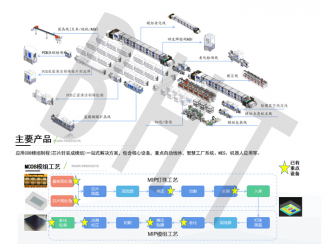

MINI/MICRO LED - COB MODULE SOLUTIONA one-stop solution for COB module process (chip packaging into modules), including core equipment, key automatic lines, smart factory systems, MES, robot applications, etc.Detail

-

MINI/MICRO LED - MIP PACKAGING SOLUTIONA one-stop solution for lamp bead packaging process using MIP technology (chip packaging into RGB/monochrome lamp beads), including core equipment, key automatic line bodies, smart factory systems, MES, robot applications, etc.Detail

-

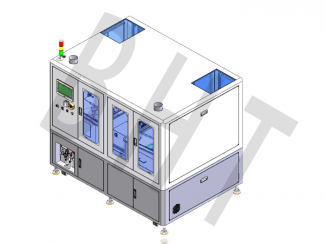

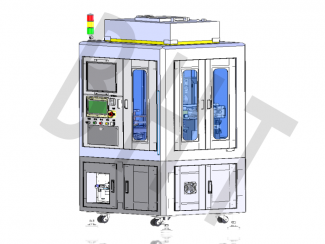

VACUUM HOT PRESSING MACHINEIntroduction:

The module vacuum hot pressing machine is a device developed by our company for the requirements of defoaming, pressure holding, and molding of display module after film coating. Place the module board after film coating into the vacuum chamber and positive pressure chamber in sequence, and use a heating device to ensure that the film coating is bubble free and tightly adhered.Detail -

MODULE LAMINATING MACHINEIntroduction:

Mainly applicable to the film coating process of SMD, COB, and GOB products in Mini/Micro LED manufacturing. Our company provides two mainstream types (atmospheric film sticking machine and vacuum film sticking machine) with the characteristics of uniform film sticking speed, no bubbles, no fragments, no wrinkles, etc. After microscopic comparison and aging verification, its film cutting accuracy, edge contour, sealing quality and other indicators are superior to similar imported equipment.Detail -

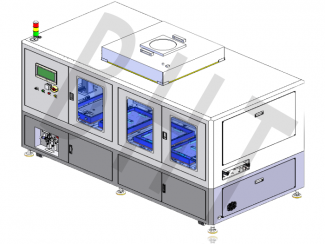

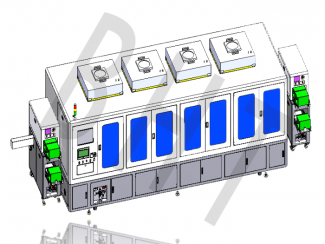

CLEANING MACHINEIntroduction:

The slicing cleaning machine is a cleaning equipment developed by our company for the cutting process of lamp beads, used to remove impurities such as powder and debris on the surface of the lamp beads after cutting; Using pure water high-pressure jet flushing and utilizing high-speed centrifugal force to effectively remove surface impurities; The combination of high-pressure air knife and rotating centrifugal force ensures no residual water stains. It can be operated as a standalone machine or produced online in a production line; Compatible with manual and crane loading and unloading.Detail -

POINT MEASUREMENT SORTING SMT MACHINEIntroduction:

The point testing and sorting surface mount machine is an independently developed cutting-edge process equipment by our company, which integrates high-speed electrical testing, appearance inspection, sorting, and surface mounting functions for semiconductor packages. It demonstrates comprehensive performance of high speed, efficiency, precision, reliability, and stability. It can be operated as a standalone machine or produced online in a production line; Compatible with manual, overhead crane, and ground rail handling vehicles for loading and unloading.Detail -

BLUE FILM EXPANSION MACHINEIntroduction:

The blue film expansion machine is a fully automatic expansion equipment developed by our company for the current manual semi-automatic expansion process. Transfer the blue film chip from the patch ring to the expansion ring, and expand the chip (lamp bead) spacing according to the set multiplier. It integrates multiple functions such as blue film chip transfer, crystal expansion ring combination, crystal expansion, blue film edge cutting, chip direction recognition, labeling or coding, and surface mount ring reflow. It can be operated independently or produced online.Detail -

BLUE FILM POURING MACHINEIntroduction:

The blue film rewinding machine is the industry’s first cutting-edge equipment independently developed by our company, which can fully automatically flip the chips (light beads) on the old blue film and apply them onto the new blue film. The overall process flow and its various process links have obtained multiple invention patents and utility model patents, and some are in the process of applying for approval. It can be operated independently or produced online.Detail -

INTELLIGENT EQUIPMENT - PCB/BT BOARD EXPANSION AND CONTRACTION DETECTION MACHINEIntroduction:

The PCB expansion and contraction detection equipment is a visual inspection device developed by our company to meet higher quality control requirements for PCB boards, BT boards, PI boards and other board materials with slight dimensional deviations. By detecting the length and width dimensions of the effective area of various types of boards, calculating their expansion and contraction, and classifying them according to predetermined standards. Provide process basis for subsequent processes, ensure accurate parameters, and improve quality.Detail -

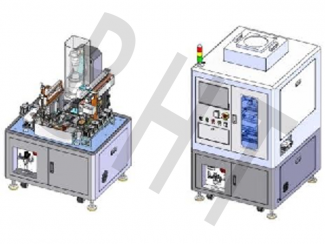

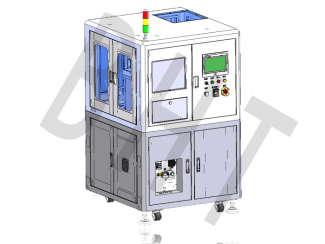

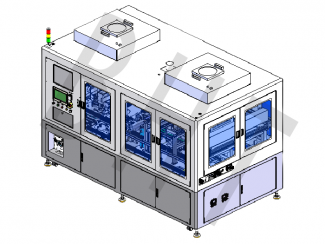

INTELLIGENT EQUIPMENT - MOLDING MACHINEbrief introduction

The fully automatic molding machine belongs to the semiconductor packaging equipment, which is applied in the film pressing process of MIP lamp beads and modules in the MiniLED process, and can also be used in the chip plastic packaging process. Using release film assisted packaging, the packaging adhesive is flattened and cured on the surface of the substrate or module to form a protective film, which provides waterproof, dustproof, and anti-collision protection for components such as chips and light beads. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.Detail

-

About usGroup profile Qualification Corporate culture Competitiveness Global layout

-

Product3C semiconductor Hydrogen Energy Automotive Related Equipment

-

ServiceResource Q&A

-

NewsCompany news Exhibition

Contact us

Copyright @ 2022-2023 Bright Automatrix Inc.

Are you interested in being

Are you interested in beinga great listed company?

+86-135 1084 6501

+86-135 1084 6501

info_433227

info_433227

David.Cao@bright-ai.com

David.Cao@bright-ai.com