-

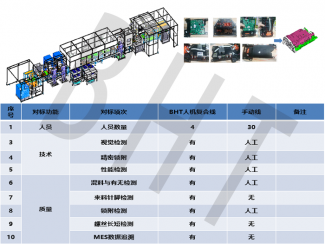

Automatic BDU Assembly-Test lineThe automatic BDU assembly testing line is used for the assembly and testing production line of automotive engine assembly control modules.

The entire line is divided into three main parts (PCBA substrate inspection section, shell&PCBA assembly section, and product testing and cutting section):

The first part covers (PCBA substrate inspection section): PCBA board automatic feeding, 2D AOI inspection, 3D AOI inspection, ICT testing, substrate burning, and semi functional testing;

The second part covers (shell&PCBA assembly section): upper shell and PCBA gluing assembly, lower shell laser engraving assembly, hook bending assembly, air tightness testing, and product static placement.

The third part covers (product testing and cutting section): high load testing, high temperature aging, functional testing, vehicle program updates, installation of ventilation valves, finished product barcode printing, PIN needle detection, product cutting, and box labeling.Detail -

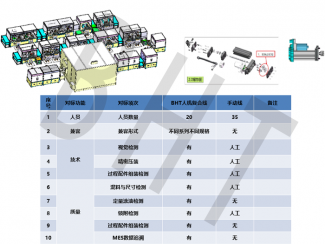

ASSEMBLY AND TESTING LINE FOR ELECTRIC SIDE DOOR ACTUATORThis device is used for the intelligent assembly and testing production line of the full braking control module in the car body area

The entire line is divided into two main parts (PCBA assembly coating section and shell assembly testing section):

The first part covers (PCBA assembly coating section): PCBA board feeding, automatic burning, PCBA board pins, PCBA board surface three proof paint coating, PIN pin coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.

Application scenarios

Applied to the integrated production scenario of assembly and testing of electric side door actuators for automobiles, equipped with real-time monitoring electronic dashboards for the entire production line, the product can achieve traceability of production technical parameters.Detail -

FULLY AUTOMATIC DOMAIN CONTROL ASSEMBLY AND TESTING LINE BODYThree proof paint coating on the surface of the board, PIN needle coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.Detail -

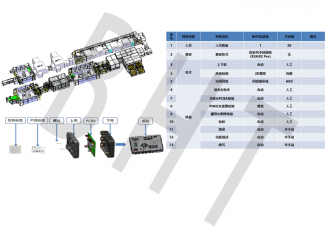

FULLY AUTOMATIC ECU ASSEMBLY AND TESTING LINEThis equipment is used for the assembly and testing production line of automotive engine assembly control modules.

The entire line is divided into three main parts (PCBA substrate inspection section, shell&PCBA assembly section, and product testing and cutting section):

The first part covers (PCBA substrate inspection section): PCBA board automatic feeding, 2D AOI inspection, 3D AOI inspection, ICT testing, substrate burning, and semi functional testing;

The second part covers (shell&PCBA assembly section): upper shell and PCBA gluing assembly, lower shell laser engraving assembly, hook bending assembly, air tightness testing, and product static placement.

The third part covers (product testing and cutting section): high load testing, high temperature aging, functional testing, vehicle program updates, installation of ventilation valves, finished product barcode printing, PIN needle detection, product cutting, and box labeling.Detail

-

About usGroup profile Qualification Corporate culture Competitiveness Global layout

-

Product3C semiconductor Hydrogen Energy Automotive Related Equipment

-

ServiceResource Q&A

-

NewsCompany news Exhibition

Contact us

Copyright @ 2022-2023 Bright Automatrix Inc.

Are you interested in being

Are you interested in beinga great listed company?

+86-135 1084 6501

+86-135 1084 6501

info_433227

info_433227

David.Cao@bright-ai.com

David.Cao@bright-ai.com