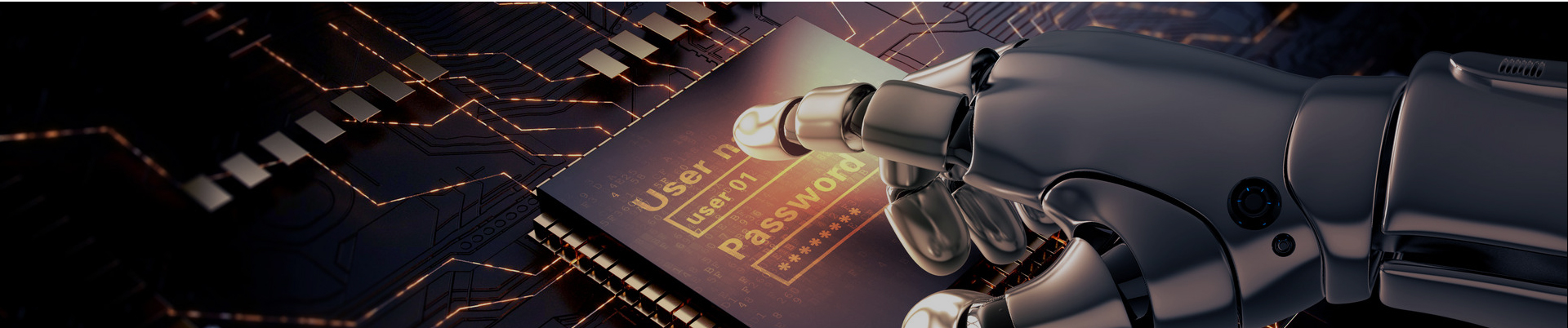

COMPRESSION MOLDING MACHINE

The fully automatic molding machine belongs to the semiconductor packaging equipment, which is used in the post packaging film pressing process of chips and can also be used in the chip plastic packaging process. Using release film assisted packaging, the packaging adhesive is flattened and cured on the surface of the substrate or module to form a protective film,

It provides waterproof, dustproof, and anti-collision protection for chips and other components. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.

It provides waterproof, dustproof, and anti-collision protection for chips and other components. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.

Product application areas

The fully automatic molding machine belongs to the semiconductor packaging equipment, which is used in the post packaging film pressing process of chips and can also be used in the chip plastic packaging process. Using release film assisted packaging, the packaging adhesive is flattened and cured on the surface of the substrate or module to form a protective film,

It provides waterproof, dustproof, and anti-collision protection for chips and other components. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.

key parameter

Equipment capacity: One to one U PH ≥ 12PCS/H; One to two UPH ≥ 24PCS/H and one to four UPH ≥ 48PCS/H (depending on the specific product process)

Yield rate: ≥ 99.8%

Product size: MAXL190xW330xmm (customizable)

Film pressure thickness: (0.2~0.6) ± 0.015mm

Equipment size: L4000xW1500xH1800mm

It provides waterproof, dustproof, and anti-collision protection for chips and other components. Our company has successfully developed various models such as one to one, one to two, and one to four, which can operate independently or be produced online.

key parameter

Equipment capacity: One to one U PH ≥ 12PCS/H; One to two UPH ≥ 24PCS/H and one to four UPH ≥ 48PCS/H (depending on the specific product process)

Yield rate: ≥ 99.8%

Product size: MAXL190xW330xmm (customizable)

Film pressure thickness: (0.2~0.6) ± 0.015mm

Equipment size: L4000xW1500xH1800mm

Related product

-

COMPRESSION MOLDING MACHINEDetail