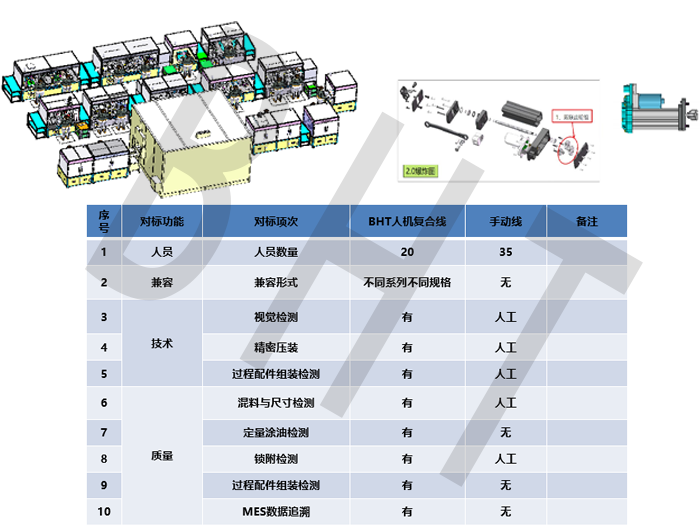

ASSEMBLY AND TESTING LINE FOR ELECTRIC SIDE DOOR ACTUATOR

This device is used for the intelligent assembly and testing production line of the full braking control module in the car body area

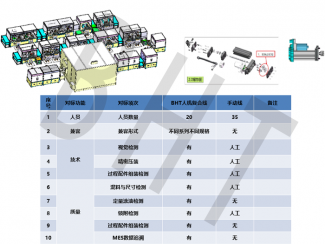

The entire line is divided into two main parts (PCBA assembly coating section and shell assembly testing section):

The first part covers (PCBA assembly coating section): PCBA board feeding, automatic burning, PCBA board pins, PCBA board surface three proof paint coating, PIN pin coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.

Application scenarios

Applied to the integrated production scenario of assembly and testing of electric side door actuators for automobiles, equipped with real-time monitoring electronic dashboards for the entire production line, the product can achieve traceability of production technical parameters.

The entire line is divided into two main parts (PCBA assembly coating section and shell assembly testing section):

The first part covers (PCBA assembly coating section): PCBA board feeding, automatic burning, PCBA board pins, PCBA board surface three proof paint coating, PIN pin coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.

Application scenarios

Applied to the integrated production scenario of assembly and testing of electric side door actuators for automobiles, equipped with real-time monitoring electronic dashboards for the entire production line, the product can achieve traceability of production technical parameters.

Product application areas

This device is used for the intelligent assembly and testing production line of the full braking control module in the car body area

The entire line is divided into two main parts (PCBA assembly coating section and shell assembly testing section):

The first part covers (PCBA assembly coating section): PCBA board feeding, automatic burning, PCBA board pins, PCBA board surface three proof paint coating, PIN pin coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.

Application scenarios

Applied to the integrated production scenario of assembly and testing of electric side door actuators for automobiles, equipped with real-time monitoring electronic dashboards for the entire production line, the product can achieve traceability of production technical parameters.

parameter

Capacity: 100PCS/H (monthly capacity can reach 50000 pcs/month/double shift)

Yield rate: 99%

Applicable products: Front door electric actuators (left and right), rear door electric actuators (left and right)

The entire line is divided into two main parts (PCBA assembly coating section and shell assembly testing section):

The first part covers (PCBA assembly coating section): PCBA board feeding, automatic burning, PCBA board pins, PCBA board surface three proof paint coating, PIN pin coating detection;

The second part covers (shell assembly testing section): shell&PCBA assembly, barcode labeling, shell screw locking, copper bar inspection assembly, functional testing, fuse and nut assembly, tear resistant labels, EU labels, dust-proof cotton attachment, and finished product program configuration testing.

Application scenarios

Applied to the integrated production scenario of assembly and testing of electric side door actuators for automobiles, equipped with real-time monitoring electronic dashboards for the entire production line, the product can achieve traceability of production technical parameters.

parameter

Capacity: 100PCS/H (monthly capacity can reach 50000 pcs/month/double shift)

Yield rate: 99%

Applicable products: Front door electric actuators (left and right), rear door electric actuators (left and right)

Related product

-

ASSEMBLY AND TESTING LINE FOR ELECTRIC SIDE DOOR ACTUATORDetail