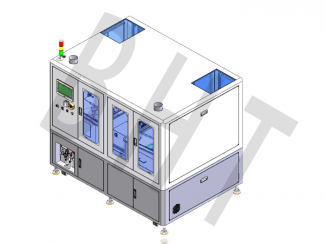

POINT MEASUREMENT SORTING SMT MACHINE

Introduction:

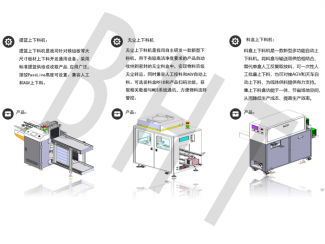

The point testing and sorting surface mount machine is an independently developed cutting-edge process equipment by our company, which integrates high-speed electrical testing, appearance inspection, sorting, and surface mounting functions for semiconductor packages. It demonstrates comprehensive performance of high speed, efficiency, precision, reliability, and stability. It can be operated as a standalone machine or produced online in a production line; Compatible with manual, overhead crane, and ground rail handling vehicles for loading and unloading.

The point testing and sorting surface mount machine is an independently developed cutting-edge process equipment by our company, which integrates high-speed electrical testing, appearance inspection, sorting, and surface mounting functions for semiconductor packages. It demonstrates comprehensive performance of high speed, efficiency, precision, reliability, and stability. It can be operated as a standalone machine or produced online in a production line; Compatible with manual, overhead crane, and ground rail handling vehicles for loading and unloading.

Product application areas

Core Technology:

High speed directional arrangement and supply of micro packages; High speed visual inspection system and its algorithm

High life, high-precision probe station and test card; Multi axis high-speed linkage control

Multi channel high-speed rotation positive and negative pressure control; High speed positioning and reversing of micro package body

High speed, high inertia, high-precision XY axis movement control; Electrical control, software and integration, etc

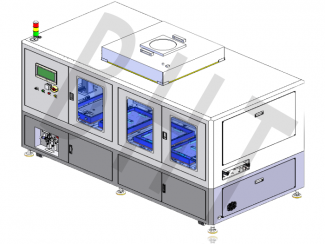

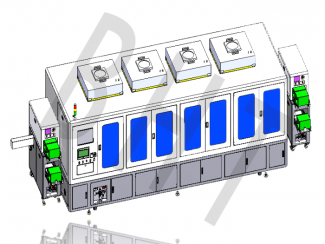

Key parameters:

Equipment capacity: UPH ≥ 45K/H (varies according to product size and time)

Product size: ≥ L0.6xW0.3mm (customizable)

Surface mount media: Blue film expansion ring and surface mount ring, PCB module board

Yield rate: ≥ 99.8%

Surface mount range: Max Φ 100mm (customizable)

Surface mount placement accuracy: X/Y ± 0.025mm, θ ± 1.5 °

Equipment size: L1050xW1100xH1700mm

High speed directional arrangement and supply of micro packages; High speed visual inspection system and its algorithm

High life, high-precision probe station and test card; Multi axis high-speed linkage control

Multi channel high-speed rotation positive and negative pressure control; High speed positioning and reversing of micro package body

High speed, high inertia, high-precision XY axis movement control; Electrical control, software and integration, etc

Key parameters:

Equipment capacity: UPH ≥ 45K/H (varies according to product size and time)

Product size: ≥ L0.6xW0.3mm (customizable)

Surface mount media: Blue film expansion ring and surface mount ring, PCB module board

Yield rate: ≥ 99.8%

Surface mount range: Max Φ 100mm (customizable)

Surface mount placement accuracy: X/Y ± 0.025mm, θ ± 1.5 °

Equipment size: L1050xW1100xH1700mm