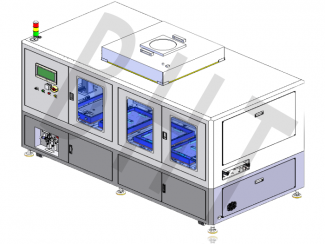

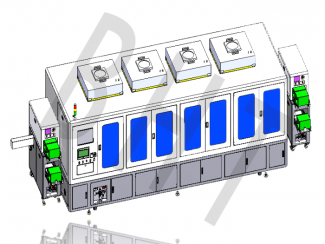

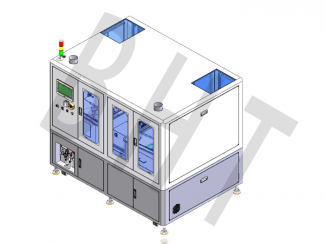

VACUUM HOT PRESSING MACHINE

Introduction:

The module vacuum hot pressing machine is a device developed by our company for the requirements of defoaming, pressure holding, and molding of display module after film coating. Place the module board after film coating into the vacuum chamber and positive pressure chamber in sequence, and use a heating device to ensure that the film coating is bubble free and tightly adhered.

The module vacuum hot pressing machine is a device developed by our company for the requirements of defoaming, pressure holding, and molding of display module after film coating. Place the module board after film coating into the vacuum chamber and positive pressure chamber in sequence, and use a heating device to ensure that the film coating is bubble free and tightly adhered.

Product application areas

Core Technology:

Uniform heating and temperature control of the module

Vacuum defoaming and its chamber sealing

Positive pressure shaping and its chamber locking and sealing

Positive and negative air pressure control and maintenance

Key parameters:

Product size: Max L190xW330mm (customizable)

Equipment capacity: UPH ≥ 30PCS/H (adjusted according to the required duration of the product)

Chamber pressure: Vacuum -99Kpa; Positive pressure 6kg/cm ²

Heating temperature: 50~80 ℃

Equipment size: L1850xW1350xH1650mm

Uniform heating and temperature control of the module

Vacuum defoaming and its chamber sealing

Positive pressure shaping and its chamber locking and sealing

Positive and negative air pressure control and maintenance

Key parameters:

Product size: Max L190xW330mm (customizable)

Equipment capacity: UPH ≥ 30PCS/H (adjusted according to the required duration of the product)

Chamber pressure: Vacuum -99Kpa; Positive pressure 6kg/cm ²

Heating temperature: 50~80 ℃

Equipment size: L1850xW1350xH1650mm