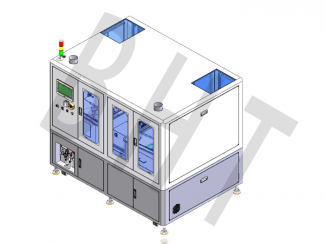

MODULE LAMINATING MACHINE

Introduction:

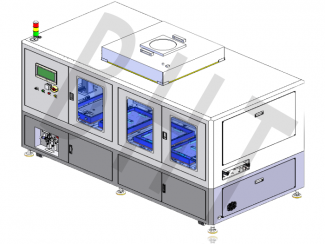

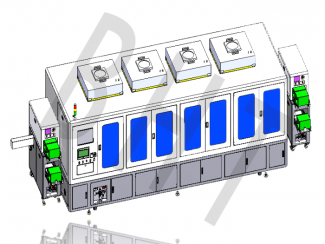

Mainly applicable to the film coating process of SMD, COB, and GOB products in Mini/Micro LED manufacturing. Our company provides two mainstream types (atmospheric film sticking machine and vacuum film sticking machine) with the characteristics of uniform film sticking speed, no bubbles, no fragments, no wrinkles, etc. After microscopic comparison and aging verification, its film cutting accuracy, edge contour, sealing quality and other indicators are superior to similar imported equipment.

Mainly applicable to the film coating process of SMD, COB, and GOB products in Mini/Micro LED manufacturing. Our company provides two mainstream types (atmospheric film sticking machine and vacuum film sticking machine) with the characteristics of uniform film sticking speed, no bubbles, no fragments, no wrinkles, etc. After microscopic comparison and aging verification, its film cutting accuracy, edge contour, sealing quality and other indicators are superior to similar imported equipment.

Product application areas

Core Technology:

High precision real-time control and adjustment of the temperature of the film carrier and film material suction plate;

Heating of film roller and precise control of temperature and multi-stage pressure;

High vacuum bonding defoaming process, multi-layer cavity pressure difference detection and control;

Module optional non-contact transport and transmission, innovative vacuum exhaust and defoaming technology

Key parameters:

Product size: Type A: L (130-350) * W (130-250) * T (1.5-3) mm

Type B: L (MAX200) * W (MAX250) * T (1.5-3) mm

Equipment capacity: 120PCS/H (depending on specific process)

Equipment size: Type A: L1350xW1250xH1800mm

Type B: 6580mm (L) x 1840mm (W) x 2000mm (H)

High precision real-time control and adjustment of the temperature of the film carrier and film material suction plate;

Heating of film roller and precise control of temperature and multi-stage pressure;

High vacuum bonding defoaming process, multi-layer cavity pressure difference detection and control;

Module optional non-contact transport and transmission, innovative vacuum exhaust and defoaming technology

Key parameters:

Product size: Type A: L (130-350) * W (130-250) * T (1.5-3) mm

Type B: L (MAX200) * W (MAX250) * T (1.5-3) mm

Equipment capacity: 120PCS/H (depending on specific process)

Equipment size: Type A: L1350xW1250xH1800mm

Type B: 6580mm (L) x 1840mm (W) x 2000mm (H)