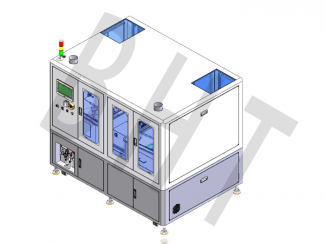

CLEANING MACHINE

Introduction:

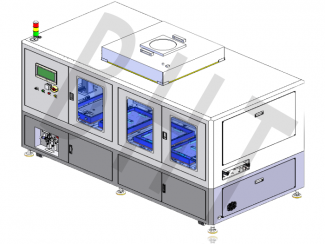

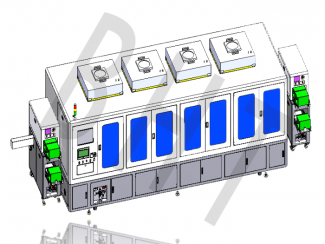

The slicing cleaning machine is a cleaning equipment developed by our company for the cutting process of lamp beads, used to remove impurities such as powder and debris on the surface of the lamp beads after cutting; Using pure water high-pressure jet flushing and utilizing high-speed centrifugal force to effectively remove surface impurities; The combination of high-pressure air knife and rotating centrifugal force ensures no residual water stains. It can be operated as a standalone machine or produced online in a production line; Compatible with manual and crane loading and unloading.

The slicing cleaning machine is a cleaning equipment developed by our company for the cutting process of lamp beads, used to remove impurities such as powder and debris on the surface of the lamp beads after cutting; Using pure water high-pressure jet flushing and utilizing high-speed centrifugal force to effectively remove surface impurities; The combination of high-pressure air knife and rotating centrifugal force ensures no residual water stains. It can be operated as a standalone machine or produced online in a production line; Compatible with manual and crane loading and unloading.

Product application areas

Core Technology:

High speed rotation start control technology for cleaning platform

Multi sheet fixed anti detachment technology under high centrifugal force conditions

Water circulation and sealing anti leakage technology

Jet water flow pressure and flow regulation control

Key parameters:

Equipment capacity: UPH ≥ 180PCS/H (depending on the specific situation of powder impurities)

Production qualification rate: ≥ 99.8%

Product size: L100xW72mm (customizable)

Equipment size: L1800xW1250xH1800mm (excluding FFU and tri color light)

High speed rotation start control technology for cleaning platform

Multi sheet fixed anti detachment technology under high centrifugal force conditions

Water circulation and sealing anti leakage technology

Jet water flow pressure and flow regulation control

Key parameters:

Equipment capacity: UPH ≥ 180PCS/H (depending on the specific situation of powder impurities)

Production qualification rate: ≥ 99.8%

Product size: L100xW72mm (customizable)

Equipment size: L1800xW1250xH1800mm (excluding FFU and tri color light)