- 3C

-

semiconductor

- Chip inverted film crystal expandingline

- AUTOMATIC WAFER TEARING MACHINE

- COMPRESSION MOLDING MACHINE

- AOI DETECTOR

- AUTOMATIC WAFER LAMINATING MACHINE

- WAFER VACUUM COATING MACHINE

- INTELLIGENT TRANSMISSION SYSTEM

- MINI/MICRO LED APPLICATION SCENARIOS

- MINI/MICRO LED - COB MODULE SOLUTION

- MINI/MICRO LED - MIP PACKAGING SOLUTION

- INTELLIGENT EQUIPMENT

-

Hydrogen Energy

- INTRODUCTION TO HYDROGEN ENERGY

- ELECTROLYZER SMART FACTORY (2.5GWH ELECTROLYZER INTELLIGENT MANUFACTURING SOLUTION)

- ELECTROLYTIC CELL POLE FRAME VERTICAL MILLING AUTOMATIC LINE BODY

- ELECTROLYTIC CELL MACHINE FRAME VERTICAL CAR INTELLIGENT LINE BODY

- AUTOMATIC WELDING LINE FOR ELECTROLYTIC CELL PLATES

- ELECTROLYTIC CELL INTELLIGENT EQUIPMENT (STANDARD EQUIPMENT)

- INFORMATION SYSTEM (STANDARD MES)

- HYDROGEN STORAGE BOTTLE SMART FACTORY (SOLUTION)

- FUEL CELL SMART FACTORY (SOLUTION)

- INTRODUCTION TO LITHIUM BATTERIES

- LITHIUM ION CYLINDRICAL BATTERY STANDARD WIRE

- SQUARE SHELL BATTERY MODULE PACK STANDARD LINE (AUTOMATIC)

- STANDARD LINE FOR SQUARE SHELL BATTERY MODULE PACK (SEMI-AUTOMATIC)

- STANDARD WIRE FOR SOFT PACK BATTERY MODULE

- CELL THICKNESS MEASURING MACHINE

- BATTERY CELL ADHESIVE MACHINE

- CELL STACKER/MODULE LOADING EQUIPMENT

- CROSS LINE POLARITY DETECTION&POLE GUIDE ADDRESS

- CROSS LINE LASER WELDING MACHINE

- Customized equipment - photovoltaic

- Automotive Related Equipment

- SMART FACTORY

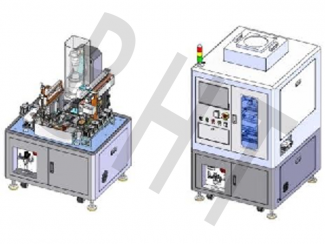

AOI DETECTOR

-

AOI DETECTORAOI inspection machine is a visual inspection equipment developed by our company for chips in new cutting processes, used to control quality issues such as cutting size and appearance. We use independently developed visual systems and algorithm software to detect the cutting quality of chips from both sides. It can be operated as a standalone machine or produced online in a production line; Compatible with manual and crane loading and unloading.Detail